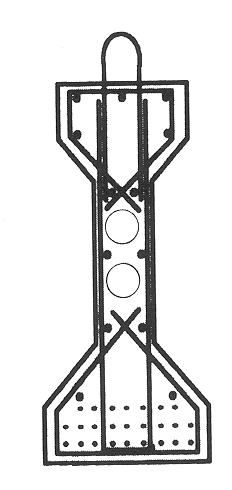

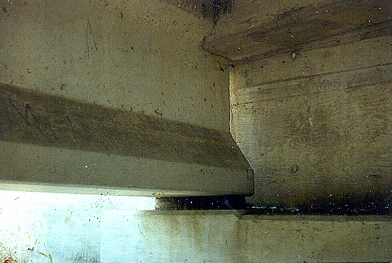

Prestressed concrete I-beams are usually constructed as simple spans (not continuous over piers) and, after erecting them, made semi-continuous by casting a transverse concrete diaphragm over the piers which also fills the gap between the beam ends. The first prestressed I-beams were constructed in Ohio in 1958, although not widely used until the early 1990s. These types of beams have been relatively maintenance-free thus far, although sealing the fascia beams is recommended on a regular basis.

Preventive Maintenance Recommendations:

- Seal the fascia beams with a silane/siloxane sealer every 5 years.

- On overpass bridges, watch for nicks, gouges and spalls in the beams caused by overheight traffic passing below. Patch these areas as noted in the Repair Section of this Manual.